New licenses (less than $1.00/day) now available for:

Treatment, Optimization & Design (Sasspro®V2) software for Activated Sludge WWTP’s

90 day – $89.00 180 day – $175.00 1 year – $300.00 Perpetual – $998.00

Go to: http://store.wedotanks.com/software-for-wwtp-design/ to order and get immediate download.

The pump is backed up to the pump-out opening with a vehicle (can be tractor or pickup). Recommended size of opening is 4′ x 6′ for ease of lowering pump.

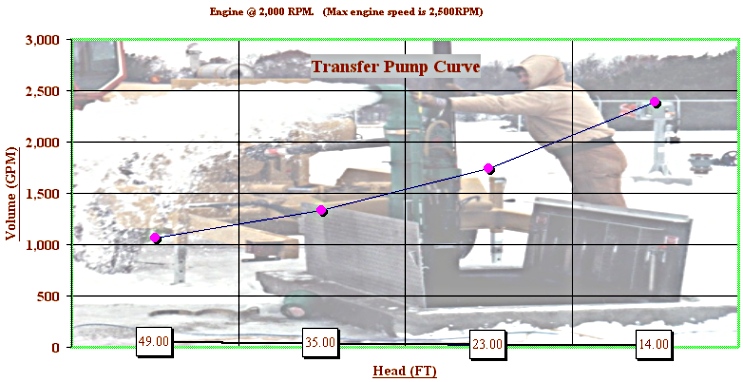

Specifications:

- 150 HP Diesel Engine

- Heavy duty trailer (6,000 lb. axles)

- Large 20″ dia. impeller with self cleaning blades

- Dual agitation nozzles

- 100 gallon fuel tank

The operator then raises the pump to a vertical position with the easily accessible controls.

Operator then lowers the pump into the Biosolids Storage Tank.

After the pump is lowered, the operator connects the PTO shaft.

You are now ready to begin pumping. ( after you connect the pump to a discharge line.)

After pump is lowered into tank, the contents can be agitated into a homogeneous mixture with the upper and lower agitation nozzles. During the tank loading operation the bottom nozzle is continuously agitating the tank contents.

The lower agitation nozzle can be rotated horizontally up to 200 and the upper nozzle can rotate both horizontally (200°) and vertically (60°).

Cutting edges chop up debris and rags. Large volumes are easily pumped with the large impeller.

Some other things we do: