Click on any item on side bar and go directly to that page

Add these easy to install and low maintenance Tertiary Filters to any Wastewater Treatment Facility for improved effluent quality.

New licenses (less than $1.00/day) now available for:

Treatment, Optimization & Design (Sasspro®V2) software for Activated Sludge WWTP’s .

90 day – $89.00 180 day – $175.00 1 year – $300.00 Perpetual – $998.00

Go to: http://store.wedotanks.com/software-for-wwtp-design/ to order and get immediate download. INST6ALLED BY WEDOTANKS®

To request a quote or to receive more information on Pyradeck Polishing Filters, e-mail info@wedotanks.com for Effective Tertiary Treatment

To Purchase Contact:

wedotnks.com, LLC

866-374-2083 or info@wedotanks.com.

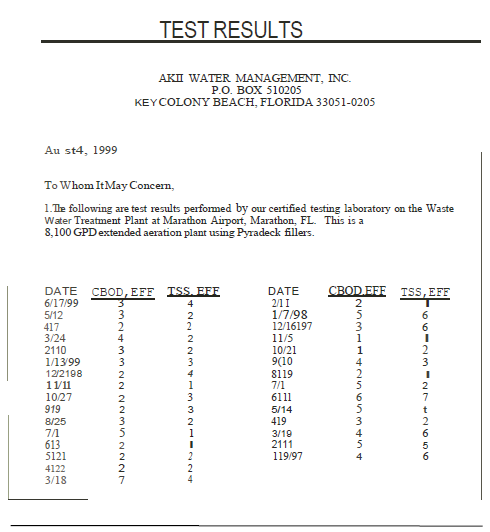

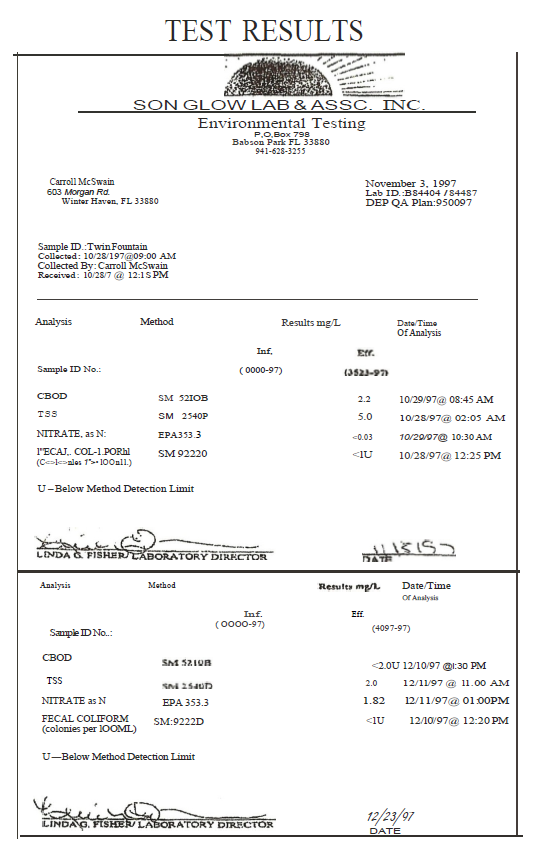

Typical:

500 Gals. I Day I Sq. Ft. …… With Flow Equalization

250 Gals. / Day l Sq. Ft. …… Without Flow Equalization

The Most Economical Means of Tertiary Treatment Available

B.O.D………………………….5PPM or Less

Suspend Solids………………5PPM or Less

Maintenance: Approx. ½ Hour / Day

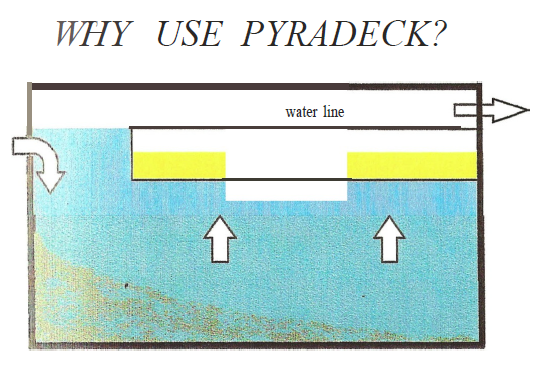

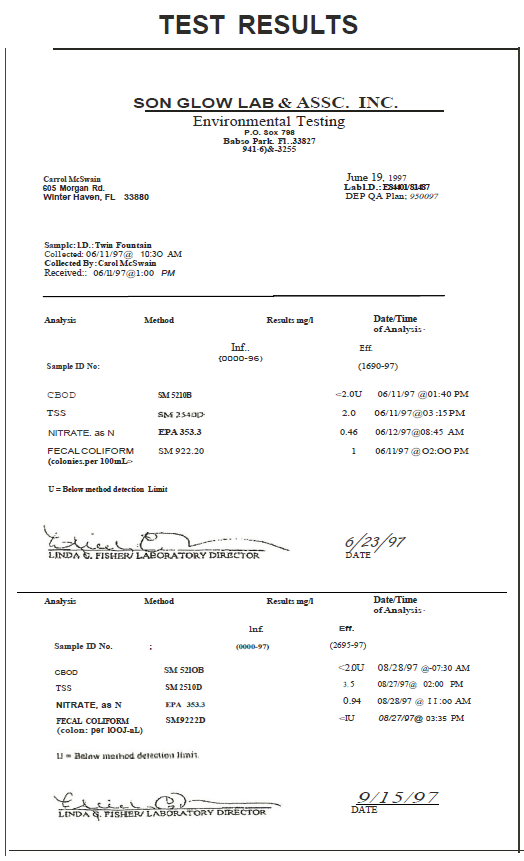

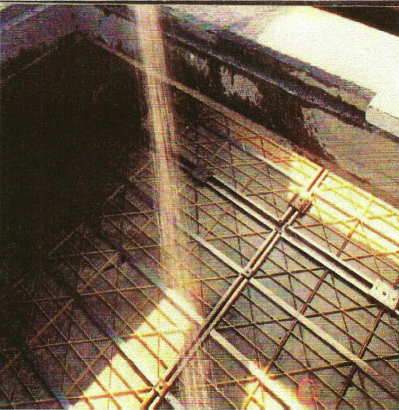

Typical Installation of a Pyradeck Upflow Clarifier

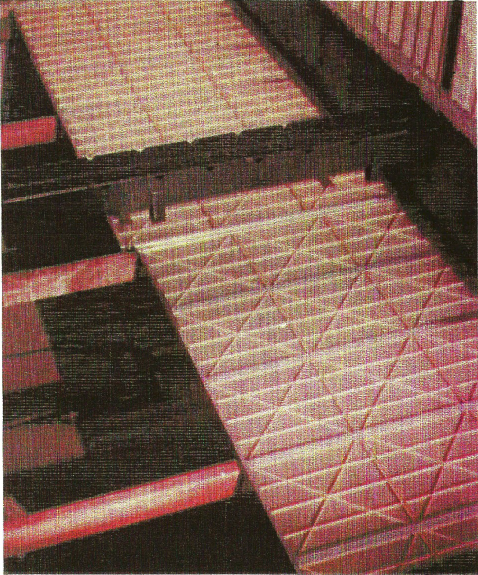

Panel Construction:

All. Pyradeck is made in 1-ft. square panel.s, any size , of tank can be decked with the material, provided that the mesh slots are arranged to lie across the breath of the tank. Trimming :border panels enables the decking to fit within a desirable l 1/4 inch clearance along the tank sides.

Each module of the assemblage used to form the deck shall be a self supporting section. Each module shall. be capable of withstanding an upthrust of 5.2 lb./ft.

Cleaning the Filter Media

Filter media usually needs to be cleaned in 7 to 10 days.

To clean the filter, the water level must be lowered by pump, below the filter media, then hosed down.

After hosing, restart operation.

The Blanket

The unique orifices in the pyradeck media create an ideal condition for collidal flock to accumulate.

The flock forms a blanket which acts as a polishing filter.

All of this is made possible by controlling the velocity of the water.

B.O.D. and suspended solids of less than 5 ppm WILL BE MET with reasonable maintenance.

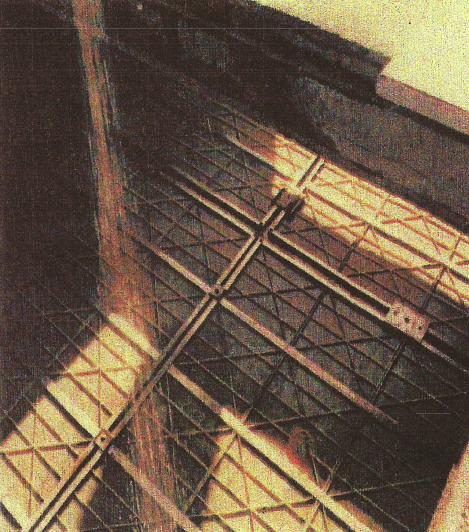

Fixed media deck

shown with blanket

of captured solids

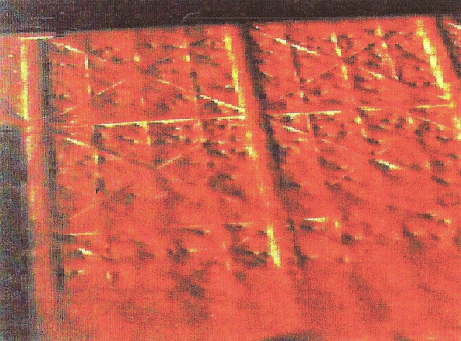

Fixed media showing

appearance of deck

after backwash

TL Contracting, Inc.

Dual Cell Fixed Media Filtration

One reinforced precast concrete fixed media filtration tank shall be supplied to remove suspended solids and B.0.D. from the effluent from a secondary sewage treatment plant. This filtration process is an upflow design through a uniform grid. As the liquid flows upward through the uniform grid (Pyradeck), a velocity change takes place that causes the solids to settle on top of the grid. When the solids are dropped out of suspension, a solid blanket forms on top of the media to further enhance the filtration process. As the suspended solid removal rate increases, a B.O.D. reduction takes place that further purifies the effluent. The unit can be cleaned by lowering the liquid level below the media and having the solids fall through the media to the bottom of the tank. Lowering the water level is accomplished by turning on the backwash pump. Complete cleaning of the tank is done by running the backwash pump until the tank is emptied. The filtration tank shall consist of two cells operating in parallel each having (insert no.) square feet of Pyradeck (fixed media), one inlet weir, one inlet baffle, redwood bracing for the media support, one 6″ adjustable outlet weir, and one (1) submersible pump in each cell be used to backwash media. Backwash is to be returned to sludge holding tank at the operator’s discretion.